Actual color may vary from on-screen representation.

Valspar® Door & Trim Oil Enriched Enamel

This enamel dries to a smooth factory-finish and stands up to daily use. Old finishes are covered with little-to-no prep work. Oil-enriched formula is as durable as traditional oils but cleanup with soap and water and resists yellowing.

Paint Sheen Comparison

Available sheens for this product

Bedrooms · Family Rooms · Hallways

Soft, low-sheen velvety finish with a slight shine; can be easily wiped down

Master Bedrooms · Formal Dining Rooms

Non-reflective finish ideal for low-traffic areas.

Kitchens · Bathrooms · Kid's Spaces

Soft lustre that can be scrubbed clean; ideal for high-traffic areas and moisture-prone rooms.

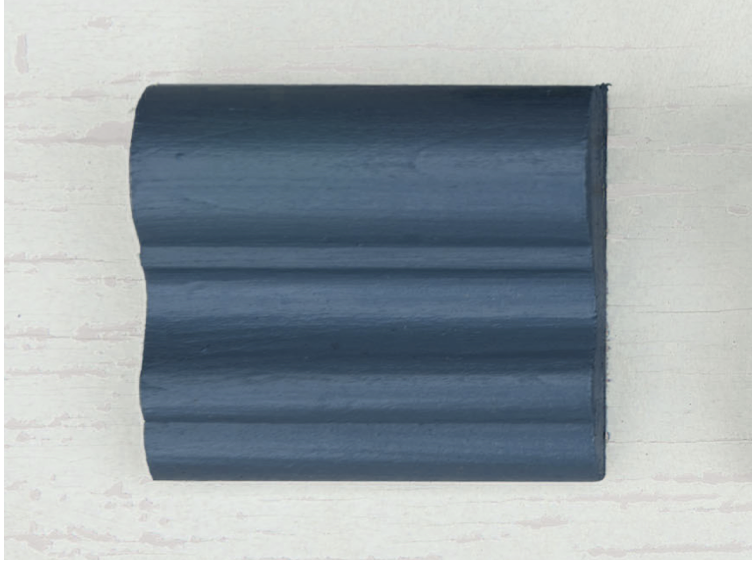

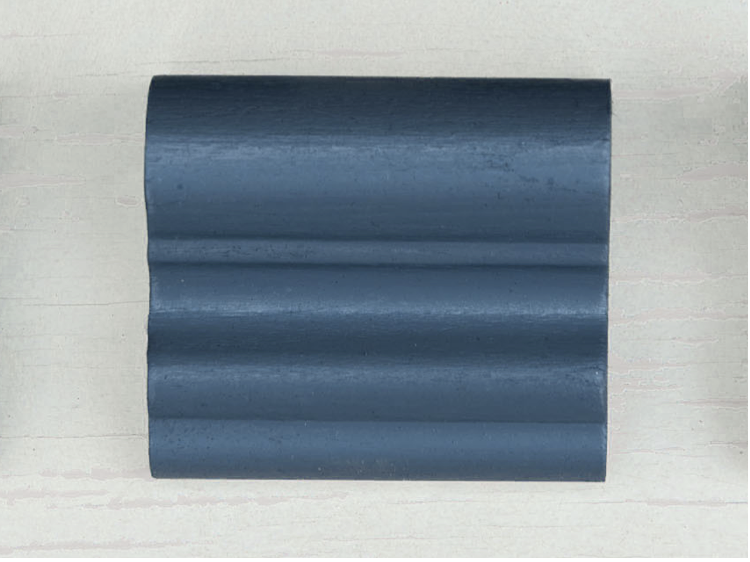

Kitchens · Bathrooms · Doors & Trim · Kid's Spaces

Shiny, mildly reflective sheen with high durability

Semi-Gloss

1 Quart

HOW TO USE

-

UsageIdeal for Wood, Metal and Laminate surfaces

-

PrepGeneral: Read the Lead Warning paragraph. Remove rust, oil, grease, mildew salt and dirt from surface. Remove all dust or other loose material off the surface. Verify area is dry and free of all dust and loose material. Previously Painted Surfaces: Follow General prep section. Glossy surfaces should be dulled. If substrate is showing prime with appropriate Valspar primer. Steel: Solvent clean all surfaces per SSPC-SP 1. SSPCSP 2, Hand Tool Cleaning is the MINIMUM pre required. SSPC-SP 6/NACE NO. 3, Commercial Blast Cleaning is PREFERRED. Galvanized: All new galvanized metal must be allowed to weather for a minimum of six months before coating. SSPC-SP 1 Solvent Cleaning is the MINIMUM prep require. SSPC-SP 16, Brush-off Blast Cleaning of Non-Ferrous Metals is PREFERRED. Drywall: Fill cracks, pits and voids with patching compound, let cure and sand smooth. Remove all sanding dust. Spot prime new or bare surfaces before applying the finish coat. Wood: Surface must be in sound condition and free from all dirt, oils and other contaminates. Solvent cleaner or other detergent might be required. Remove all loose wood by sanding as required.

-

ApplicationStir paint thoroughly. Intermix containers to ensure uniform color. Apply only when paint, surface and air temperatures are 50–90 °F (10–32 °C) during application and drying time. Brush: Use a premium-quality natural bristle brush. Roller: 3/8–3/4 inch nap, premium-quality synthetic cover. Airless spray: 2000 PSI, 0.011–0.015" tip. These recommendations are a starting point only. Due to variability in sprayers, we recommend testing your spray pattern and flow before proceeding.

-

Dry TimeDry Time @ 77 °F and 50 % Relative HumidityTo The Touch: 1 hour - 2 hour Recoat: 4 hour - 4 hour

-

Clean-up & DisposalCleanup with soap and water.

.jpg)